How laser machine will hurt in low temperature ?

Freezing temperatures can potentially harm a laser machine in several ways, it always bring huge economic losses:

- Water Tube Damage: The laser machine always contains water or water-based components, like water tubes, and water tank, freezing temperatures can cause the water to expand, leading to damage. This is especially critical in cooling systems.

- Condensation: Rapid temperature changes, such as going from freezing temperatures to a warmer environment, can cause condensation inside the machine. This moisture can damage sensitive electronic components.

- Lubrication Issues: Some parts of the laser machine may rely on lubricants. Freezing temperatures can cause these lubricants to solidify, affecting the movement and performance of mechanical components.

- Material Stress: Extreme cold can impact the materials used in the construction of the laser machine, potentially leading to cracking or other structural damage.

- Electronics: Electronic components can be sensitive to temperature extremes. Freezing temperatures may affect the functionality of circuit boards, sensors, and other electronic parts.

To prevent these issues, it’s advisable to store or use laser machines in a climate-controlled environment or take measures to winterize the equipment. This includes draining water-based systems, ensuring proper insulation, and following manufacturer recommendations for winter storage. Regular maintenance checks and adherence to storage guidelines can help mitigate the risk of damage during freezing conditions.

How to take measures to protect the laser machine from Freeze ?

If your laser equipment is equipped with a water chiller, when the chiller and laser generator are not used for a long time, you should try to drain the water in the chiller and pipes before storage.

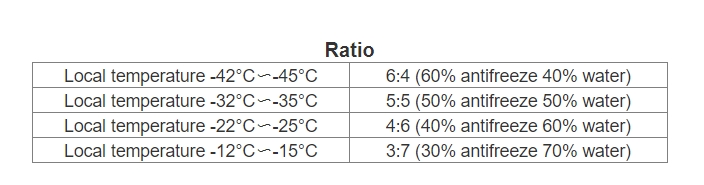

If it needs to be used frequently, adding an appropriate amount of antifreeze to the cooling water is an effective way to prevent freezing. Choose a high-quality antifreeze fluid and follow the recommended mixing ratios.

Following is the suggested antifreeze ratio in certain temperature.

Remember to turn off the power to the water cooler and drain the water from the tank before adding antifreeze.

Maintain proper equipment ambient temperature

Keep the temperature of the room where the laser equipment is located within the optimal range to avoid the ambient temperature being too low, which may cause ice to form and damage the internal structure of the machine.

MINI Jewelry welding machine

MINI jewelry welding machine is designed for goldsmiths can be a valuable tool for precision work in the jewelry industry. These machines are specifically designed to provide controlled and localized heat, allowing for precise welding and repair of jewelry pieces.

2 Responses

I like this site it’s a master piece! Glad I noticed this ohttps://69v.topn google.Money from blog

послуги seo просування сайту ціна