A spot laser welding machine can be used to weld a variety of materials, including:

- Metals: Spot laser welding machines are commonly used for welding various metals, including but not limited to:

- Steel (carbon steel, stainless steel)

- Aluminum

- Copper

- Brass

- Titanium

- Gold and other precious metals

- Alloys: They can also weld alloys and composite materials with different metal components.

- Plastics: Certain spot laser welding machines equipped with specific wavelengths can weld thermoplastics. This is particularly common in industries like automotive and electronics.

- Jewelry and Precious Metals: Spot laser welding machines are widely used in the jewelry industry for tasks like repairing fine jewelry, resizing rings, and intricate welding of precious metals.

- Electronic Components: They are used for precision welding of electronic components, particularly in the microelectronics industry.

- Dental Alloys: In the dental industry, spot laser welding machines are used for tasks like repairing dental prosthetics and creating dental appliances.

- Medical Devices: They can be used for welding various components of medical devices, particularly those made from metals and alloys.

- Automotive Components: Spot laser welding is applied in the automotive industry for tasks like welding body panels, exhaust systems, and various components within the vehicle.

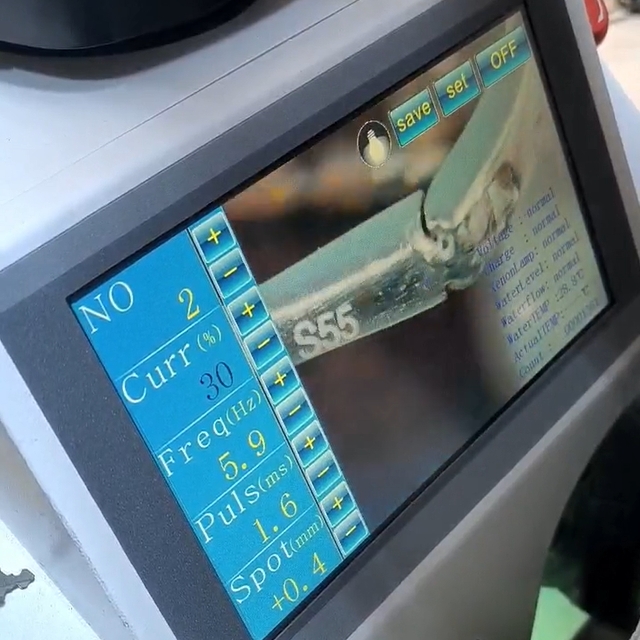

It’s important to note that the specific suitability of a spot laser welding machine for a particular material depends on factors such as the wavelength of the laser, the power output of the machine, and the specific welding parameters used. Always refer to the manufacturer’s guidelines and recommendations for the appropriate materials and settings for your specific spot laser welding machine.