150W mini Spot Laser Welding Machine for Precision Metal Welding

This 150W laser welding machine for widely used for Jewelry welding, dental welding and other precision welding. Built-in water cooling system + air cooling system makes it can working long times with excellent working ability.

Additional information

| Laser Type | YAG laser 150W |

|---|---|

| Laser Power | 150w |

| Support Language | English, Turkish, Korean, Arabic, Spanish, Chinese etc. |

| Beam Diameter | 0.1-3mm |

| Pulse width | 0.1-15ms |

| Single Pulse Energy | 80J |

| Cooling system | Built-in water cooling + air cooling |

| Machine Net weight | 45KG |

| Machine Packing Size & Weight | L760*W540*H630mm, 60KG |

Product Details:

150W MINI Spot laser welding machine is a device used for precision welding in manufacturing processes. These machines use laser technology to create localized heat, allowing for highly accurate and controlled welding of metals and other materials. Here are some key aspects and features of spot laser welding machines:

Machine’s main features:

- Laser Technology: 150W Spot laser welding machines use high-powered YAG solid-state laser, to generate a concentrated beam of light. This laser beam is focused on a small spot, creating intense heat for welding.

- Precision and Accuracy: One of the main advantages of spot laser welding is its precision. Its laser beam can reaches a range at 0.1-3mm. The focused laser beam enables welding in small and intricate areas with minimal heat affected zones. This is particularly useful for applications where precision and accuracy are crucial.

- Applications: Spot laser welding is commonly used in the manufacturing of electronic components, medical devices, jewelry, automotive parts, and other industries where small, detailed welding is required.

- Speed and Efficiency: Laser welding is often faster than traditional welding methods. The concentrated energy allows for quick melting and solidification of the material, contributing to higher efficiency in the welding process.

- Automation Integration: Spot laser welding machines can be integrated into automated manufacturing systems. This integration allows for consistent and repeatable welding processes, improving overall production efficiency.

- Controlled Energy Delivery: Laser welding machines offer precise control over the energy delivered to the workpiece. This control helps in minimizing distortion and ensuring the integrity of the welded joint.

- Versatility: These machines can weld a variety of materials, including metals, alloys, and some thermoplastics. The versatility makes them suitable for a range of applications across different industries.

- Ease of Use: Modern spot laser welding machines often come with user-friendly interfaces and programmable settings, making them accessible to operators with varying levels of expertise.

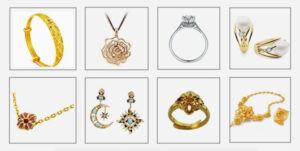

Welding Samples