Principles of Laser Welding

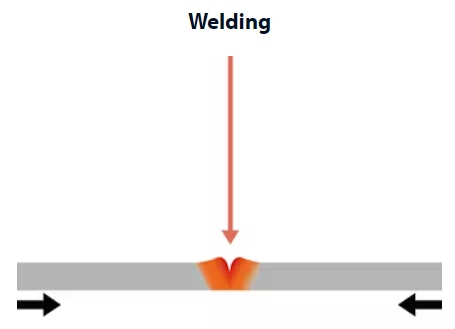

Laser welding employs a laser beam to melt and unite metal materials efficiently. This method offers higher welding speeds and reduced distortion compared to traditional welding techniques.

Laser beams, unlike the arcs in arc welding, can be precisely focused to a small point. Elevating energy density with a converging lens enables localized welding and joining of materials with distinct melting points. Laser welding excels in detailed applications, offering minimal heat effects, a thin bead, and eliminating processing reaction forces.

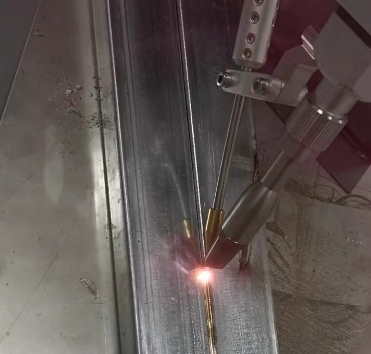

The laser beam used in welding is invisible. The medium for laser excitation can be either gas or a solid object. This excited laser, focused by a lens, is applied to the base material. Adjustable power and spot diameter cater to various processing applications beyond welding, enabling tasks such as drawing letters, patterns, and cutting.

Laser welding utilizes an exceptionally potent laser beam, surpassing those in other processes. This potent beam acts as a heat source, melting and fusing base materials.

For high-power output lasers, precise control over beam convergence properties, wavelength, energy density, intensity, and beam mode is crucial. Despite these demanding requirements, laser welding stands out for its versatility, accommodating delicate applications and seamlessly joining both thick and thin plates.

Features of Laser Welding

Characteristic

- Adaptability: Laser welding equipment, operating at atmospheric pressures, eliminates the need for a vacuum chamber found in electron beam welding. It boasts smaller equipment dimensions than electron beam welding, facilitating automation and precise control using computers or robots. Utilizing fibers and transmission path mirrors enables welding at a distance from the exciter, offering adaptability to various applications.

- Remote Capabilities: The advantages of laser welding extend to remote applications, fiber laser welding, and beam scan welding, meeting diverse welding process requirements.

The two most commonly used laser welding on the market are YAG laser welding and fiber laser welding. We will introduce the characteristics and application scope of these two welding methods in detail in the following articles.

One Response

You have remarked very interesting points! ps nice web site.Leadership