Every mechanical device has its own power rating, and laser spot welders are no exception. During use, the problem of insufficient output power of the laser spot welder sometimes occurs. Solving this problem requires specific analysis of specific problems. The following are five types of main reasons.

New machine issues:

For laser spot welders that have just left the factory, you need to check whether the power set at the factory meets the standards. At the same time, it is necessary to ensure that there is no light leakage from the fully reflective diaphragm and whether the adjustment of the resonant cavity reaches the factory specifications. If there are problems, you can ask for improvements or replacement of the equipment.

Old machine issues:

- By analyzing these five aspects in detail, we can more accurately locate problems that may lead to insufficient output power during the use of old machines, and take corresponding adjustment and maintenance measures.

- Totally reflective diaphragm is damaged:

Check whether the total reflective diaphragm is contaminated. A fouled diaphragm may reduce the laser output power and needs to be cleaned or replaced in time. - Resonator changes:

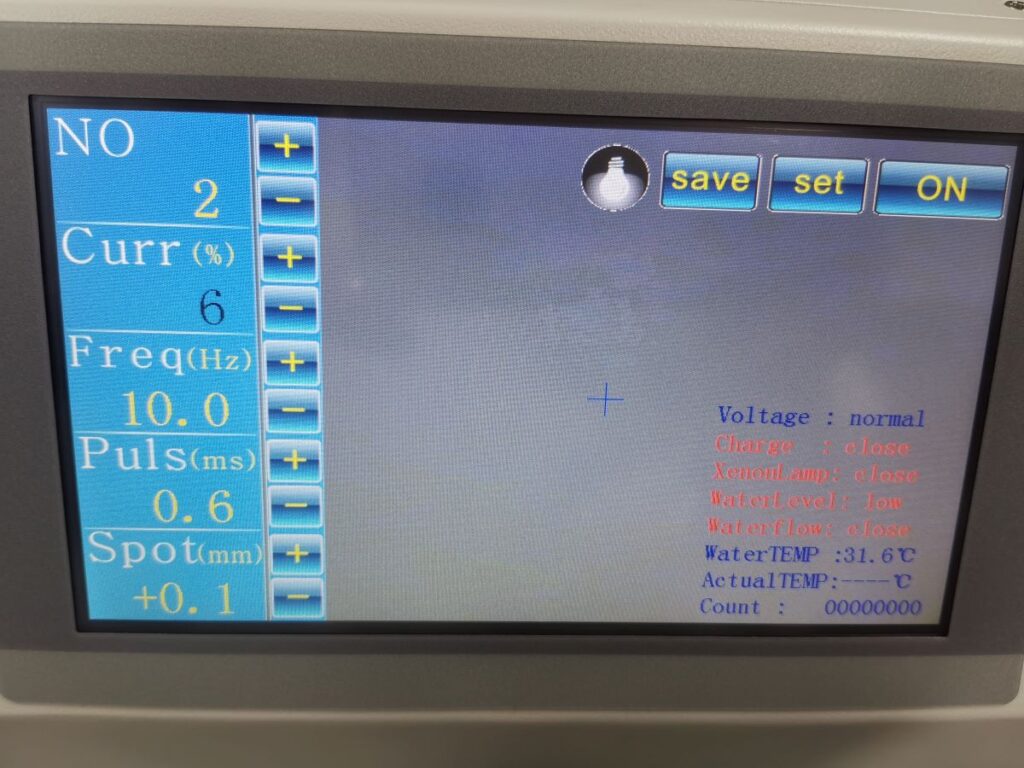

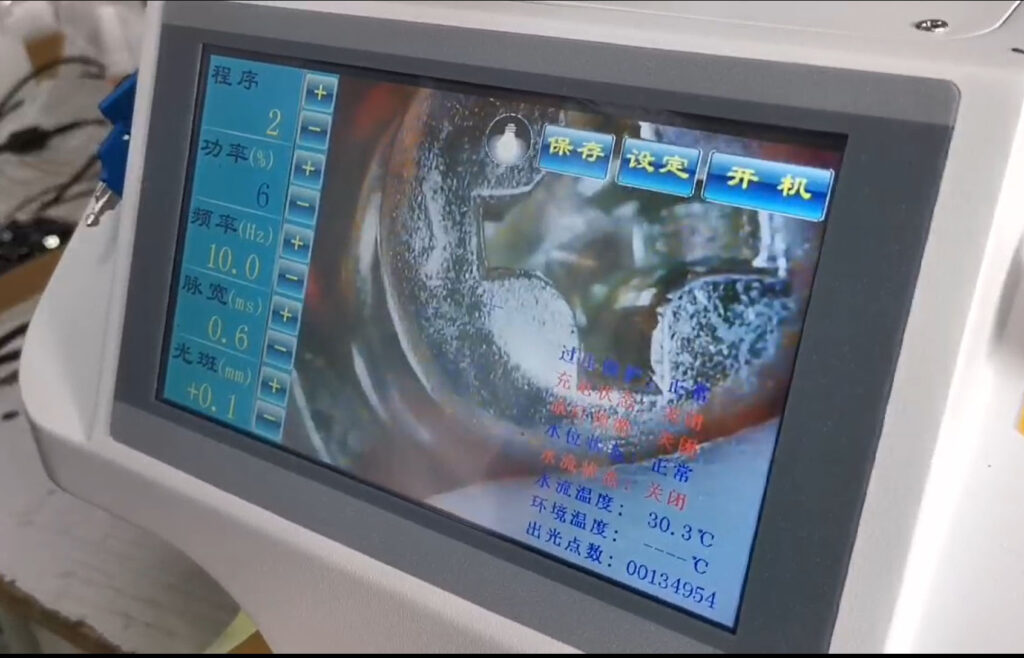

If an old machine is used for a long time, the resonant cavity may change. Careful inspection and fine-tuning are performed to ensure the condition of the resonant cavity to maintain the best output spot. - Cooling system issues:

Make sure that the temperature of the cooling water tank does not differ by more than 5 degrees from the ambient temperature. Exceeding this range may affect the normal operation of the laser machine and requires adjustment. - Xenon lamp brightness is insufficient:

Check the brightness of the Xenon lamp to make sure it is bright enough. If the Xenon lamp is nearing the end of its life, replace it in time to maintain sufficient laser output. - Acousto-optic crystal position adjustment:

Make sure the position of the acousto-optic crystal is consistent with the initial setting. If differences are found, timely adjustments need to be made to maintain the stability of the laser system.

In many cases, insufficient output power is often caused by improper use and operation. Reasonable use can reduce the occurrence of such problems and extend the service life of the laser spot welding machine.

For more details, please contact Wellbridge team any time.

Email: sales@wellbridgetech.com

80W spot laser welder for Jewelry Dental and Glasses

An 80W portable laser welder for jewelry is a specialized tool designed for precision welding of various types of jewelry metals, dental and glasses metal processing. Available for different colors: White, red and black.