Fiber lasers – excellent focusing and selectable beam quality

Fiber lasers are generated within a flexible doped glass optical fiber, typically 10-30 feet in length. long, ranging from 10 to 50 µm in diameter. Ytterbium was used as the doping element because it provides good conversion efficiency and an output wavelength close to 1 μm, which is a good match with existing laser delivery components. The laser is generated entirely within the fiber, so there is no need to align the medium with the cavity mirror, and there is no need to maintain optics and alignment as with pulsed Nd:YAG lasers. Very efficient laser processes mean fiber lasers can be small and air-cooled, and provide high electro-optical conversion efficiencies.

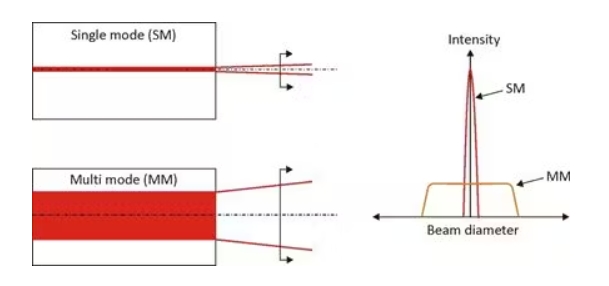

The unique properties of fiber lasers are their “focusability” and their range of beam qualities, which can be adjusted for each welding application. The two ends of the beam quality spectrum are singlemode and multimode – singlemode is defined as a beam quality (M2) <1.2, while multimode is typically above M2 = 2. The mode defines how focused and focused the laser is. The power density distributed across the laser. The figure below is a schematic diagram of single-mode and multi-mode fiber lasers.

Fiber laser is a solid-state laser that uses optical fiber as the medium.

The amplifying fiber is a type of fiber known as a “double-clad fiber” whose core is doped with rare earth elements. The exit side is also equipped with a low-reflectivity mirror, and the incident side is equipped with a high-reflectivity mirror.

In fiber laser oscillation, the excitation light generated by the exciter first enters the amplifying fiber and propagates through reflection inside the amplifying fiber.

The rare earth elements doped in the core of the amplified optical fiber absorb the excitation light, and an electron population inversion occurs between the base energy level and the metastable energy level to emit light.

The emitted light is repeatedly reflected between high-reflectivity mirrors and low-reflectivity mirrors in the resonant section, and then oscillates as a laser beam.

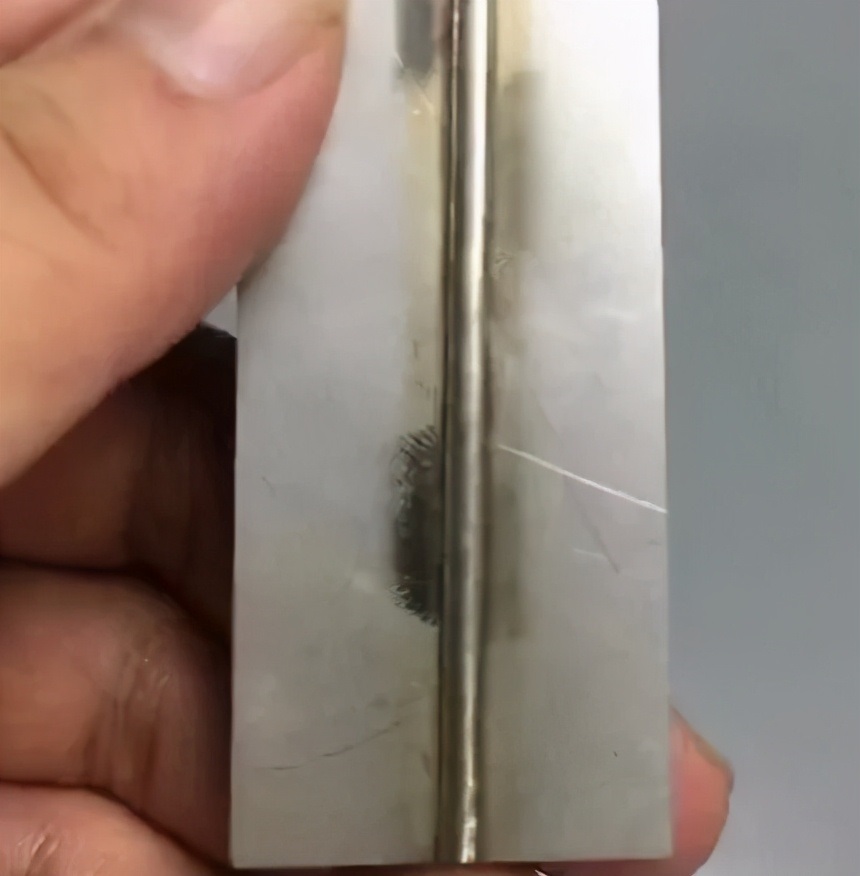

The wavelength of fiber lasers is short, and the focusing diameter of the beam can be reduced. The energy density of fiber lasers is significantly higher than that used in laser welding, allowing deep penetration even in highly reflective materials such as aluminum. In addition to welding thin plates and fine parts, fiber lasers can also be used to weld dissimilar metals. In addition, the ability to automatically set the beam focus ensures contactless, high-speed welding, allowing robotic welding to be used even in complex locations that were previously impossible.

With the advancement of technology, the laser power of continuous fiber laser welding machines has become higher and higher, and currently the most widely used one can reach 3000W. The thickness range of welding materials is also getting thicker.

More products details

-

100W YAG laser spot welding machine

-

150W mini Spot Laser Welding Machine for Precision Metal Welding

-

20-200w Pulsed fiber laser Max laser source Raycus laser

-

60W spot laser welding machine for jewelry welding

-

80W spot laser welder for Jewelry Dental and Glasses

-

Hot Sale 200w Jewelry Gold Silver Welding Repairing Soldering Machine Laser Spot Welder

-

MAX Raycus CW fiber laser source for laser welding cutting

-

MINI Jewelry welding machine

-

RV Worm Gearbox Speed Reducer